From the point of view of technical and nuclear safety and the possible

consequences of an emergency, it is necessary to have a knowledge of the state

of the entire primary circuit, i.e., about all equipment and pipeline systems

during the designed life and beyond - during Long-Term Operation (LTO).

The reactor including the reactor cover is the most critical component

in Nuclear Power Plant (NPP) from the point of view of nuclear safety. This component which is

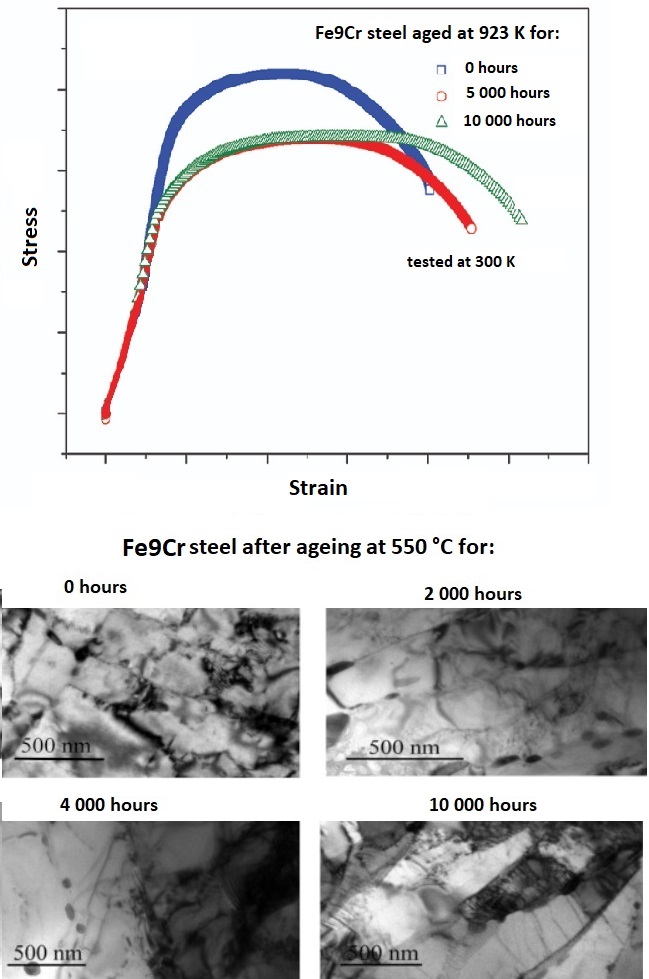

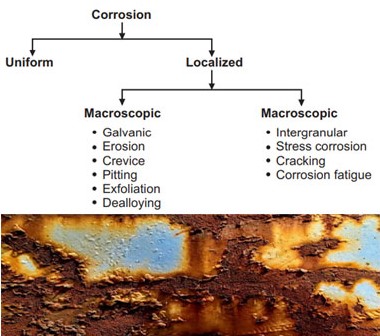

irreplaceable must withstand all degradation mechanisms such as irradiation,

thermal and mechanical stress and corrosion strain. The critical parts here are

weld joints, cladding, nozzles, and sealing surfaces. Further, the steam generator appears as critical equipment from of view

of the effects of the degradation mechanism and operation ageing. The

degradation mechanisms mostly in heat exchange tubes have an influence on

functionality, which is the transport of heat from the primary coolant water to

the secondary circuit. Further critical parts are also the Main circulation

piping - mostly their weld joints and nozzles.

The steam generator, welds and pipping are under certain circumstances replaceable.

However, any repair or replacement of equipment on the primary circuit

represents a huge financial investment by the operator, in the form of downtime

or even the repair costs themselves. In the case of LTO operation, this may

lead to the decision that further operation of the NPP is not economically

advantageous and may lead to the shutdown of the NPP. Therefore, it is

necessary to know well the ageing processes of materials during operation on

the entire primary circuit.

Factors, that have an influence on the safe operation of NPPs, are the

level of operation management, personnel qualifications, compliance with

operating regulations and especially the state of knowledge about the operated

equipment and the effect of degradation mechanisms on it. Knowledge of the

operated equipment state is determined by several factors:

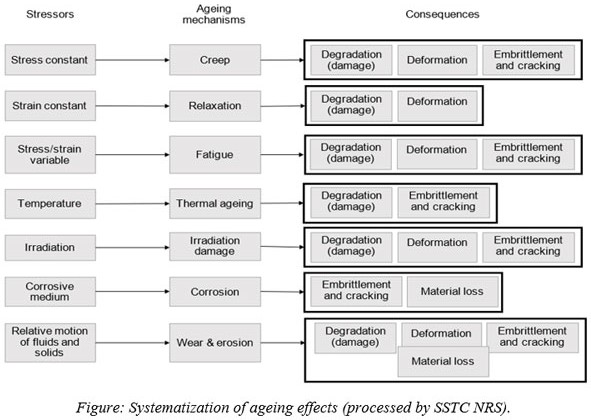

a) Knowledge of degradation mechanisms acting on the material and

components.

b) Knowledge of the effects on the ageing of materials and components

under operating conditions.

c) Level and scope of maintenance activities.

d) Level and scope of in-service inspections.

Knowledge of the effects of degradation mechanism and ageing effects

during normal operating conditions is the most important factor for correct

lifetime assessment of structure, construction and component. For this, it is

necessary to know the operating conditions and properly monitor them for any

changes.

During the identification of critical components of the VVER, we are

focused on two views: i) the increase of the safety operation at extended

lifetime due to the in-time prediction of the potential failure and recommended

construction, material, and maintenance optimisation, and ii) to the

investigation of available materials (steam generator tubes, primary pipes)

from decommissioned nuclear power plants or from material archives of the DELISA-LTO

project partners.